The Volvo EC210 excavator is a robust machine known for its performance in demanding construction applications. At the heart of this machinery lies the Vehicle Electronic Control Unit (VECU), a sophisticated electronic system that controls critical functions across the excavator.

The VECU optimizes engine parameters, hydraulic systems, and other vital components to ensure peak performance . Furthermore, it plays a crucial role in identifying potential issues through its built-in fault detection , allowing operators and technicians to address problems promptly.

When executing diagnostics on the EC210 VECU, specialized software tools are essential . These tools provide a comprehensive view of the excavator's electronic systems, enabling technicians to read real-time data, review fault codes, and configure system settings.

Regular VECU diagnostics are vital for maintaining the excavator's performance. By identifying potential issues before they escalate into major problems, proactive maintenance can extend the lifespan of the machine and minimize delays.

Decoding the Volvo EC210 VECU System

The Volvo EC210 VECU system is a sophisticated network of components responsible for governing various aspects of this versatile excavator. Investigating into the VECU's inner workings requires a deep understanding of both hydraulic systems and the proprietary software that drives it. This article aims to shed light on the key functions and design of the VECU system, equipping technicians and operators with a clearer picture of how this essential component coordinates the EC210's performance.

- Key components of the VECU system include:

- Data acquisition units that gather information about diverse excavator functions.

- Control mechanisms that manipulate hydraulic systems based on received information.

- Brain module responsible for analyzing sensor data and issuing control signals.

Delving into the EC290 Volvo Excavator Engine Control System

The EC290 is renowned for its robust performance and efficiency, largely due to its advanced electronic control unit (ECU). This system carefully monitors a multitude of parameters to optimize power output. From fuel injection, the ECU dynamically adapts to varying workload, ensuring smooth operation and reduced fuel burn.

- Intelligent sensors continuously collect information on key engine parameters.

- The information is then processed by the ECU, which determines precise adjustments to maintain optimal engine performance.

- Moreover, the EC290's ECU connects effortlessly with other machine systems, such as the hydraulics and transmission, for a coordinated operating experience.

Therefore, operators benefit from a machine that is responsive while remaining environmentally conscious. The EC290's sophisticated engine control system stands as a testament to Volvo's commitment to innovation and operational excellence.

Modeling Volvo Truck ECU for Advanced Training

Advanced automotive technicians require in-depth knowledge of Electronic Control Units (ECUs) to effectively diagnose and repair modern vehicles. Simulating a Volvo truck ECU provides a valuable training tool, allowing technicians to investigate complex systems in a risk-free environment. Through simulation software, trainees can manipulate virtual ECUs, triggering various operating conditions and observing the system's responses. This hands-on experience enhances their troubleshooting skills and equips them for real-world challenges. Furthermore, simulations can be tailored to specific training objectives, focusing on particular components or scenarios. By mastering the fundamentals of ECU simulation, technicians gain a essential edge in their careers.

Mastering Volvo VECU Technology for Improved Efficiency

Unlocking the potential check here of Volvo's Vehicle Electronic Control Unit (VECU) technology is crucial for achieving superior performance and fuel efficiency. The VECU acts as the brain of your vehicle, controlling a myriad of critical functions, from engine operation to transmission control. By understanding the intricacies of this sophisticated system, you can unlock its full potential and experience significant improvements in your vehicle's overall efficiency.

A comprehensive understanding of VECU parameters allows for adjustment of various engine and transmission settings, resulting in refined fuel consumption and power delivery. This can be achieved through the use of specialized diagnostic tools and software that provide detailed insights into the vehicle's operating parameters.

By analyzing VECU data, technicians can identify areas for improvement and make necessary adjustments to optimize performance and efficiency.

Moreover, regular maintenance and updates of the VECU software are essential to ensure its effective functioning.

Mastering Volvo VECU technology empowers you to control your vehicle's performance, leading to a more economical driving experience and reduced environmental impact.

Troubleshooting Volvo EC Series through VECU Expertise

When facing challenges with your Volvo EC Series excavator, precise diagnostics are crucial for resolving the issue efficiently. Leveraging your expertise in VECU (Volvo Electronic Control Unit) systems can provide critical insights into the machine's performance and pinpoint the source of any problems. By examining the data stored within the VECU, technicians can isolate malfunctions related to hydraulic systems, engine operation, or electronic controls. This approach allows for targeted repairs and minimizes downtime, keeping your Volvo EC Series excavator operational.

Rick Moranis Then & Now!

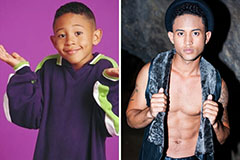

Rick Moranis Then & Now! Tahj Mowry Then & Now!

Tahj Mowry Then & Now! Shannon Elizabeth Then & Now!

Shannon Elizabeth Then & Now! Daryl Hannah Then & Now!

Daryl Hannah Then & Now! Bernadette Peters Then & Now!

Bernadette Peters Then & Now!